For the tabletop wargame and miniatures hobbyist, 3D printing has emerged as a revolutionary tool. Printing miniature models for games such as Warhammer is incredibly cost effective, and allows us create things at home that we never thought were possible. While this offers incredible value and and freedom, it's crucial to be aware of potential hazards that may arise during the 3D printing process. In this post, we will explore the significance of understanding toxic fumes emitted during 3D printing and the crucial role of ventilation in ensuring a safe printing environment.

Understanding Toxic Fumes in 3D Printing:

While 3D printing offers immense creative benefits, it's important to acknowledge that certain materials used in the process can emit toxic fumes. These fumes primarily originate from the filament or resin used, as well as from the heated print bed or nozzle.

Filaments: Various types of filaments are available for 3D printing, including ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), and PETG (Polyethylene Terephthalate Glycol). ABS, for example, can release hazardous fumes containing styrene when heated. Similarly, PLA emits ultrafine particles and volatile organic compounds (VOCs) when melted.

Resins: In the case of resin-based 3D printers, certain resins, such as those containing epoxy or acrylic components, can generate harmful fumes during the curing process. These fumes may contain volatile monomers and other chemicals that can have adverse health effects if inhaled.

Importance of Ventilation:

To mitigate the risks associated with toxic fumes, establishing proper ventilation is crucial within your 3D printing workspace. Adequate ventilation helps in several ways:

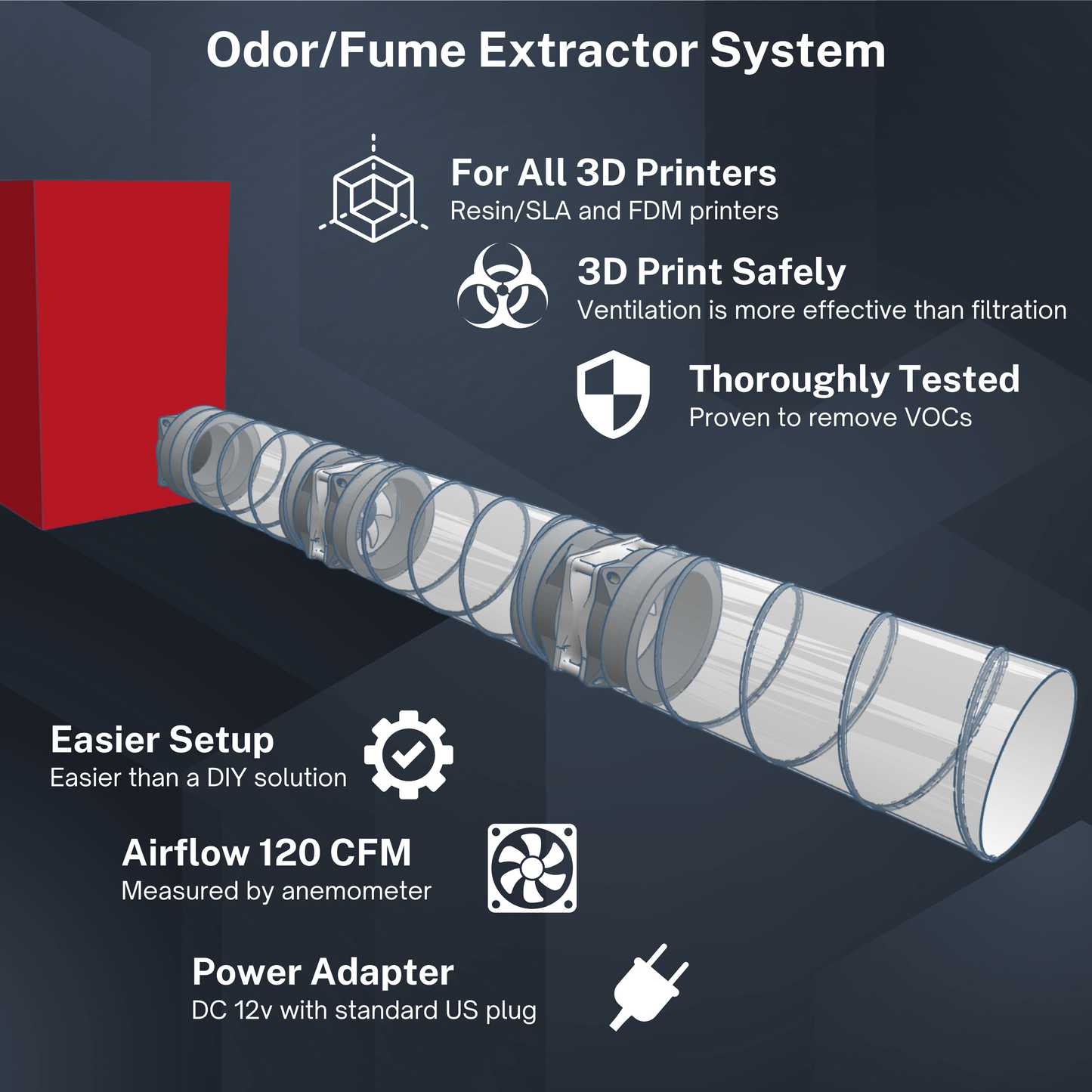

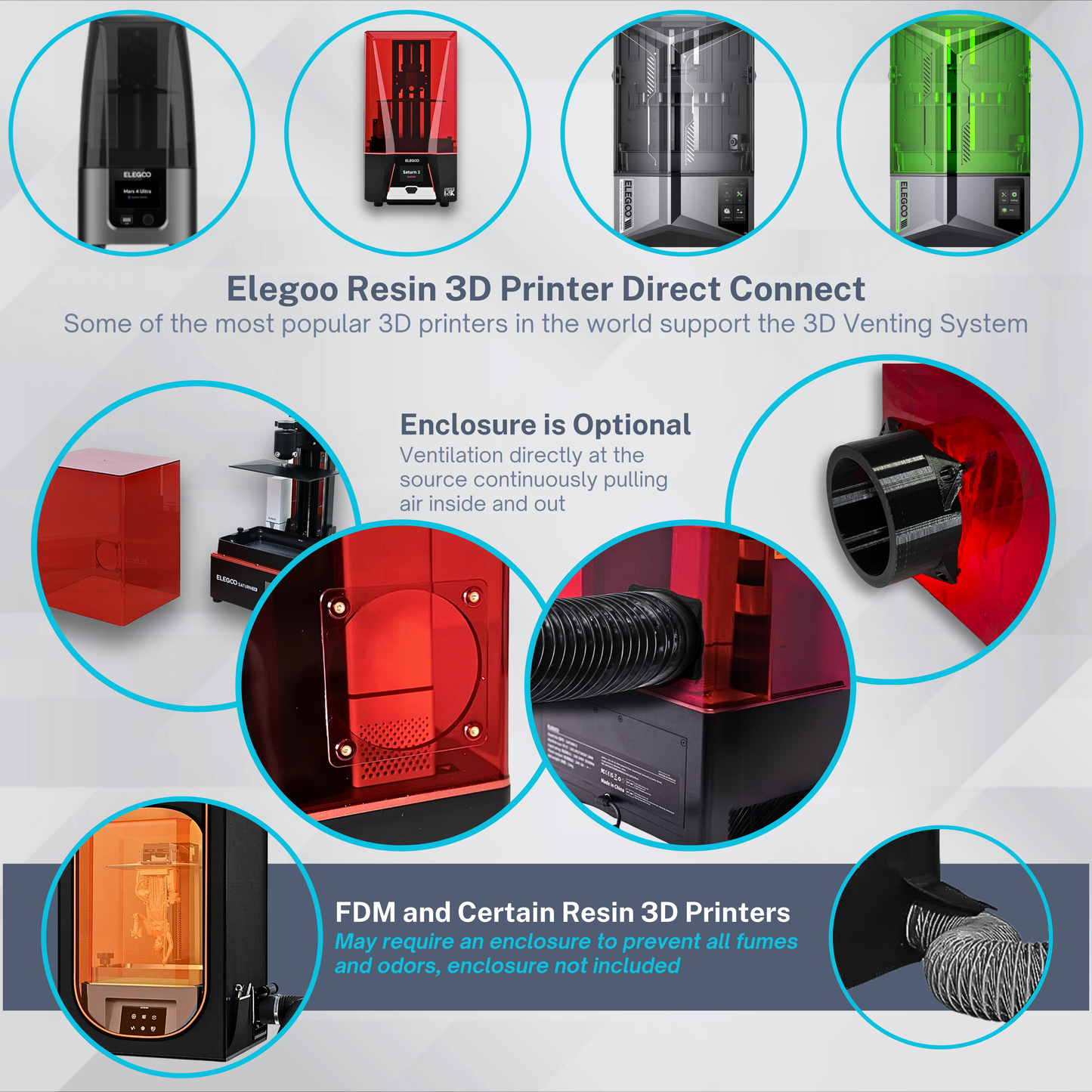

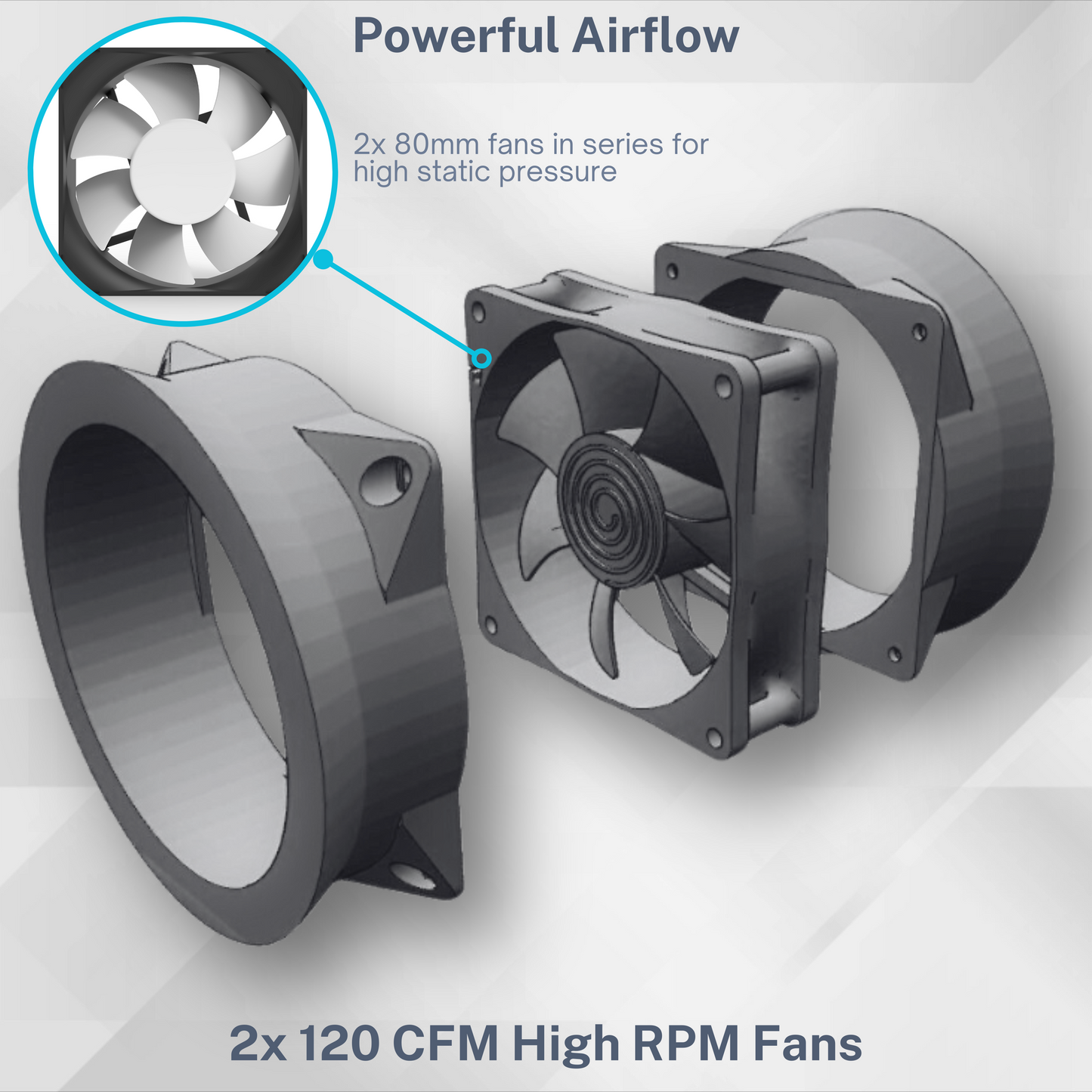

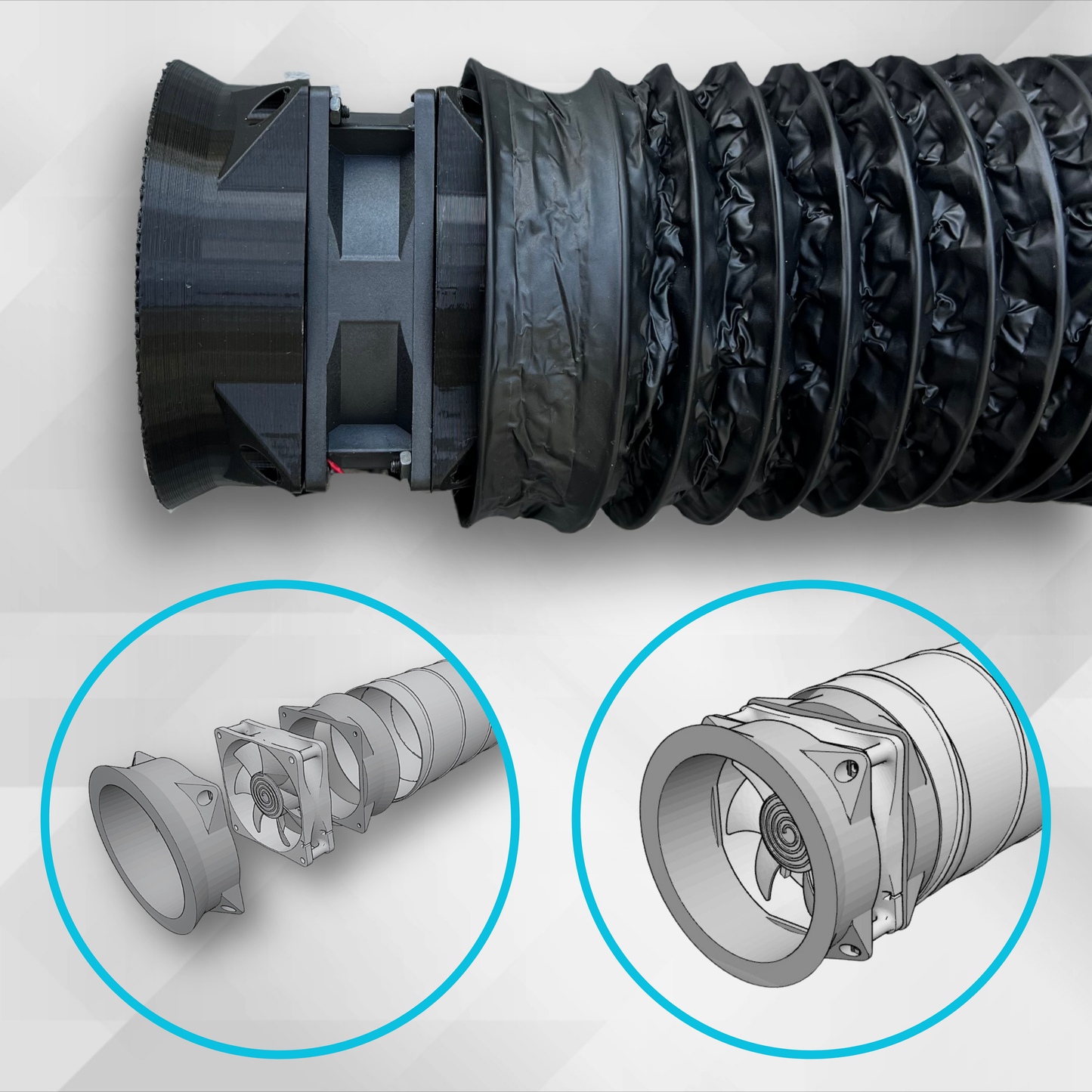

1. Fume Extraction: Efficient ventilation systems, such as fume hoods or local exhaust ventilation, remove harmful fumes directly from the printing area. These systems capture the fumes at the source, preventing their dispersion into the surrounding environment and reducing the risk of inhalation.

2. Air Purification: Utilizing air purifiers with high-quality filters can help further eliminate particulates and volatile organic compounds from the air. HEPA (High-Efficiency Particulate Air) filters are effective in capturing ultrafine particles, while activated carbon filters can absorb certain VOCs, enhancing air quality within the workspace.

3. Maintaining Temperature and Humidity: Adequate ventilation not only helps remove toxic fumes but also regulates temperature and humidity levels within the printing area. Optimal temperature and humidity conditions ensure better printing results and reduce the likelihood of material degradation or warping.

To ensure safety during 3D printing, here are some best practices to consider:

1. Work in a well-ventilated area: Choose a workspace with good air circulation and consider installing exhaust fans or opening windows to facilitate proper airflow.

2. Use materials with low emission profiles: Opt for filaments and resins that have low toxicity and emit minimal fumes during printing. Research the material safety data sheets (MSDS) provided by manufacturers to understand the potential risks.

3. Enclose the printing area: If possible, consider using an enclosed printer or setting up a dedicated enclosure around the printer. This helps contain the fumes and directs them towards the ventilation system for effective extraction.

As the world of 3D printing expands, it is essential to prioritize safety alongside creativity and latest and greatest new 12k printer. Understanding the potential hazards associated with toxic fumes and implementing proper ventilation measures within your 3D printing workspace are vital steps to safeguard your health and well-being. By being proactive and following best practices, we can fully benefit from 3D printing, while minimizing any potential risks.

VENT80 for ELEGOO Resin Printer Ventilation Odor/Fume Extractor Complete System

Regular price

$79.95 USD

Regular price

Sale price

$79.95 USD

Unit price

per