3D Printing Safety: How Our 3D Vent System Works

3D Printing Toxic Resin Fumes

Resin 3D printing fumes are toxic and harmful due to the volatile organic compounds (VOCs) released during the printing process, which can irritate the respiratory system and potentially cause long-term health effects. It is important to operate resin 3D printers in well-ventilated areas or employ proper ventilation systems to minimize exposure to these toxic fumes.

Resin 3D printing fumes are toxic and harmful due to the volatile organic compounds (VOCs) released during the printing process, which can irritate the respiratory system and potentially cause long-term health effects. It is important to operate resin 3D printers in well-ventilated areas or employ proper ventilation systems to minimize exposure to these toxic fumes.3D Printing Safety

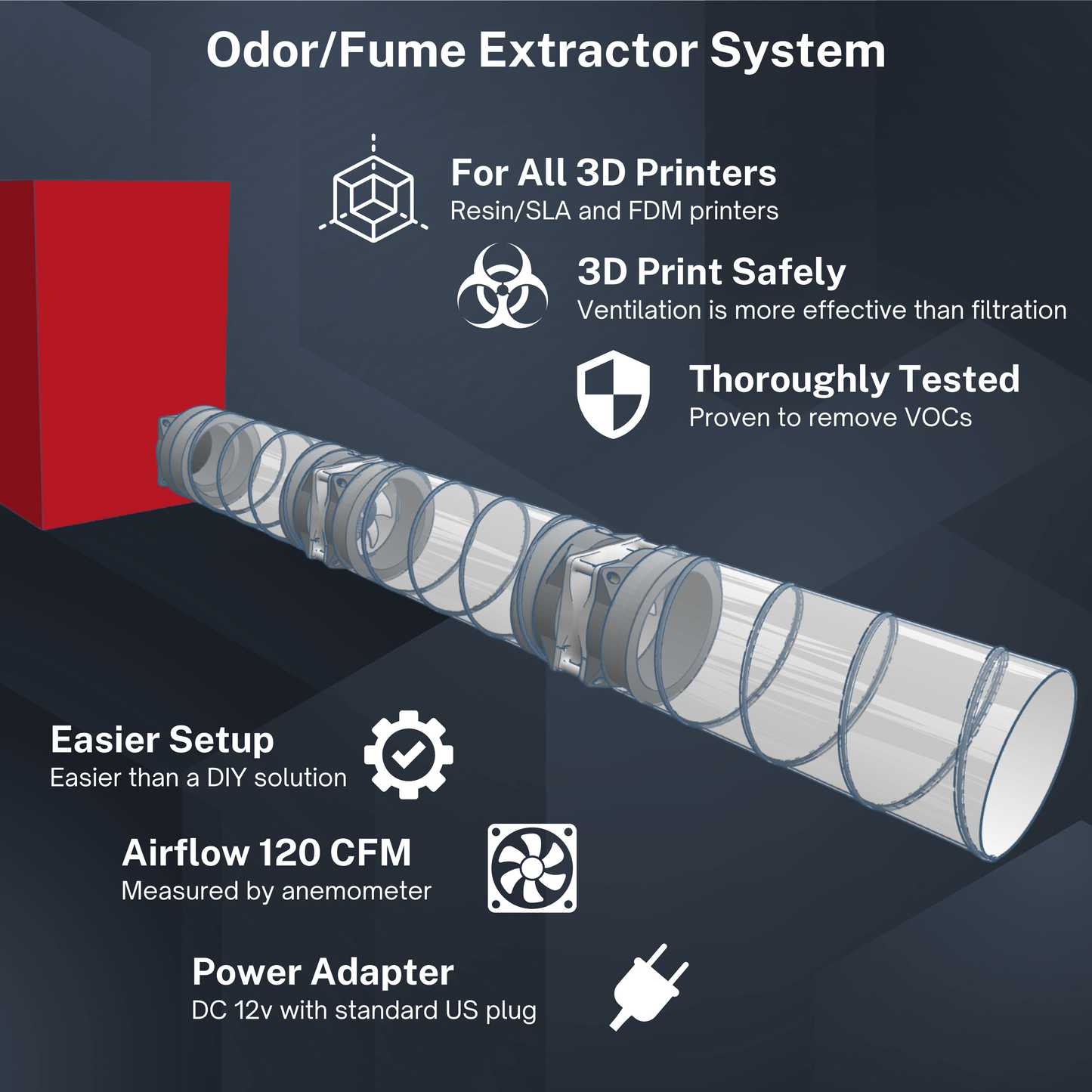

We recommend venting outdoors as it is the safest solution. Carbon adsorption filters have shown mixed results when testing effectiveness. It is more reliable and costs less to vent directly to the outside. Carbon air filters will need to be frequently replaced. However, both venting and filtering can be effective solutions for 3D printing when used correctly. For more information read our article about Understanding 3D Printing Emissions.

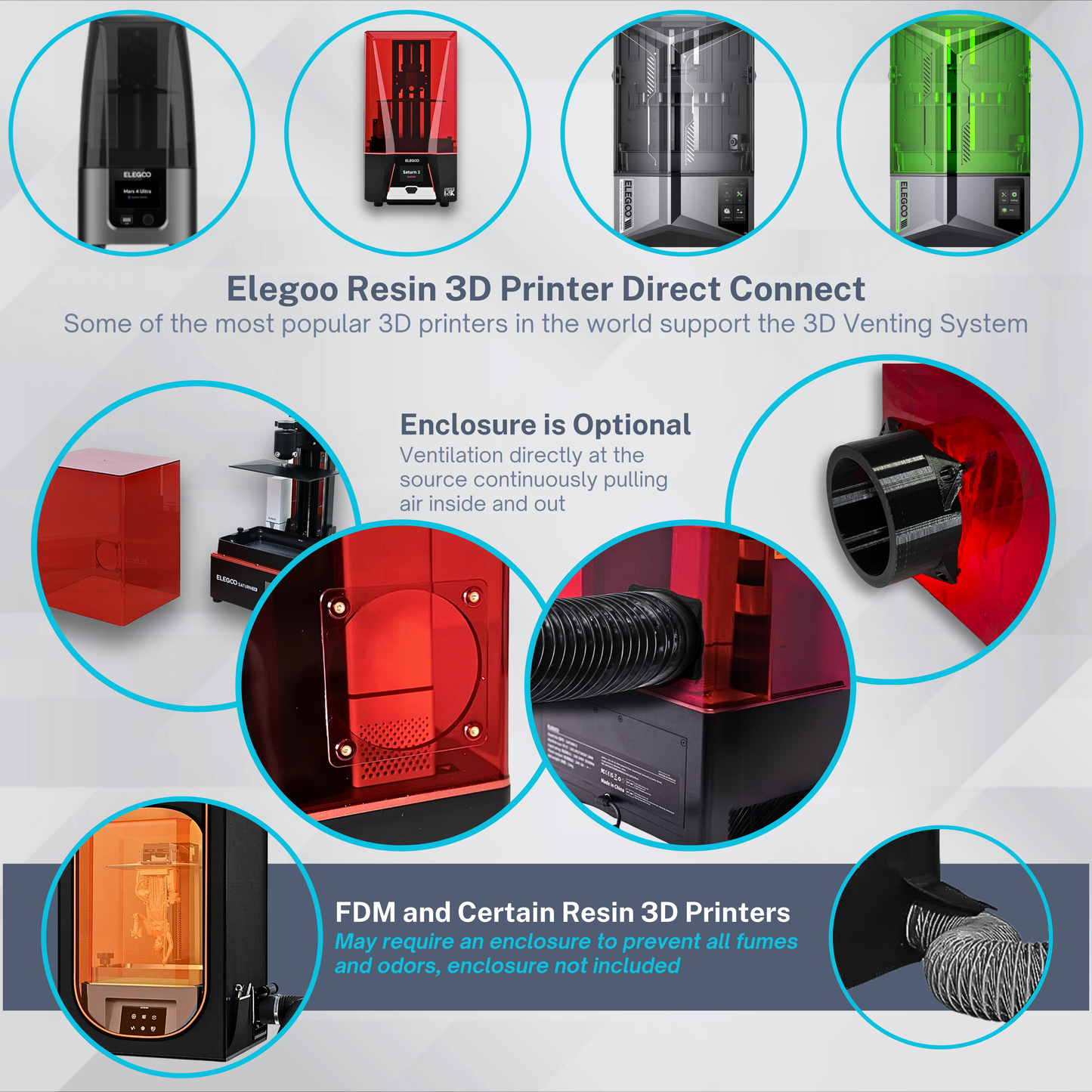

Many resin 3d printers such as the Elegoo Saturn line, have an exhaust port for exactly this purpose. Alternatively, some 3d printers may expel air from a vent on the machine, which provides another mount point for ventilation. If neither of these options works for your setup, then we provide a template for drilling a few small holes in the polycarbonate UV cover. Our attachment adapters work for all these applications.

Testing Effectiveness

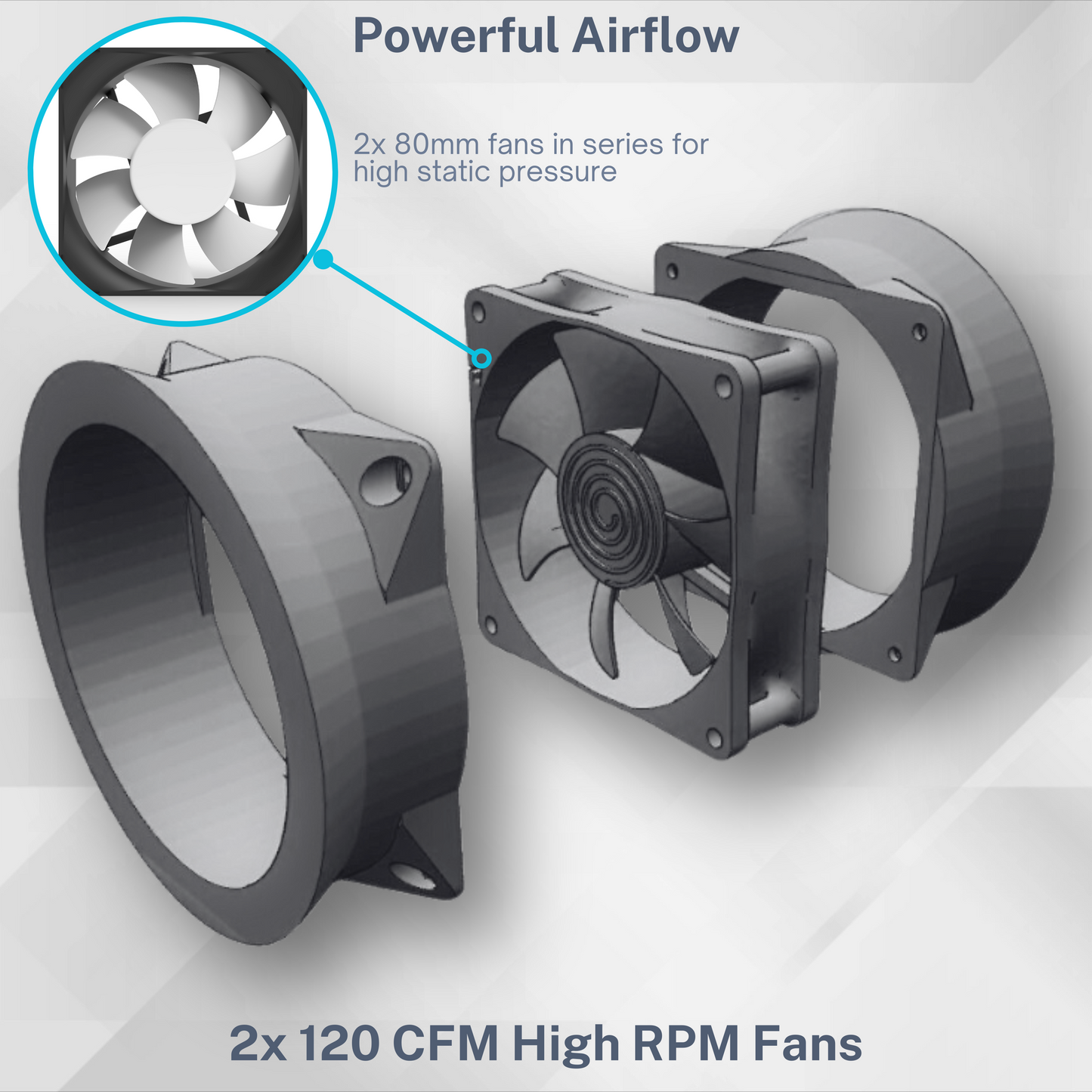

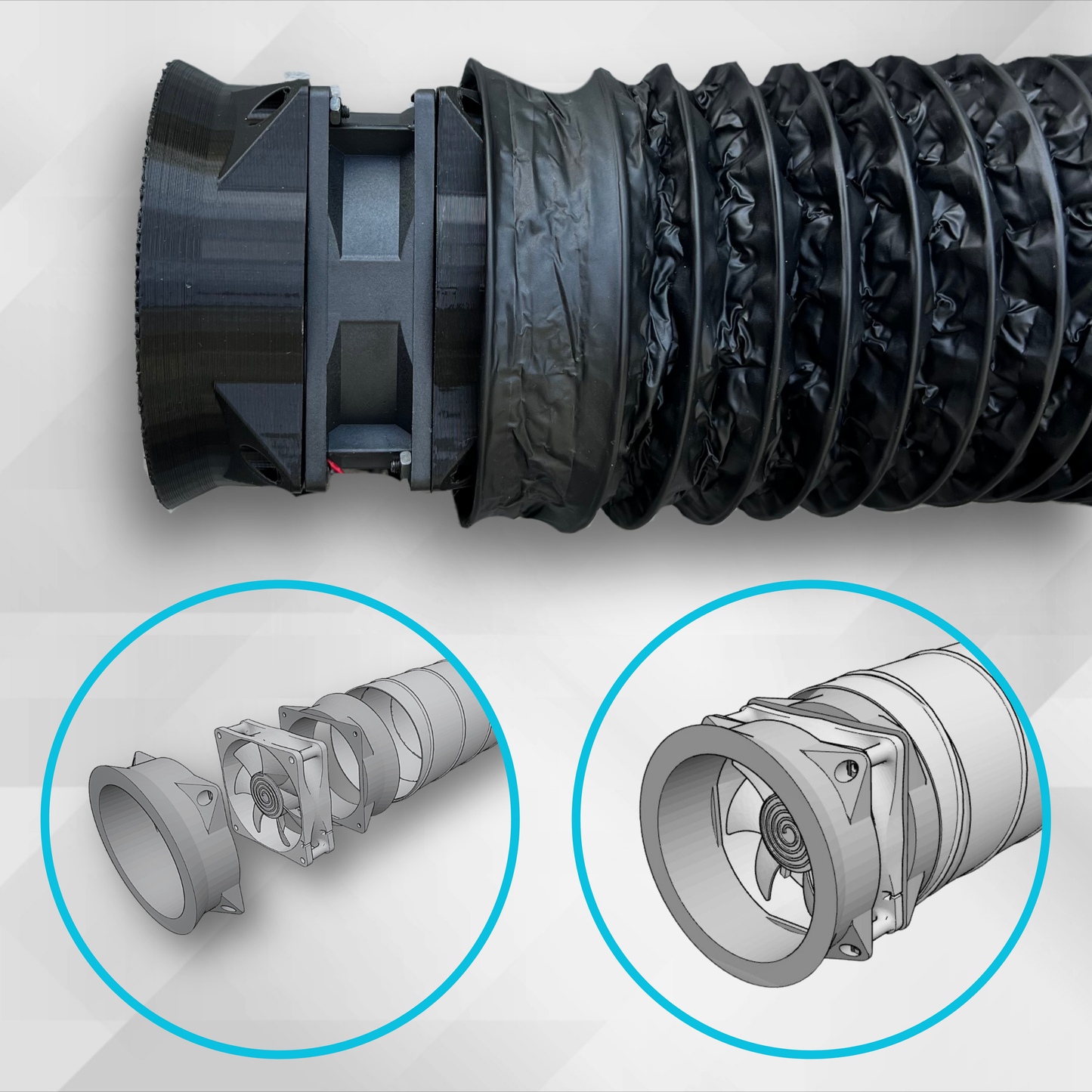

Running two fans inside the 4" duct achieves an airflow of 7 MPH or 650 LFM. LFM measures the air speed, in feet per minute as it moves past a point.

Running two fans inside the 4" duct achieves an airflow of 7 MPH or 650 LFM. LFM measures the air speed, in feet per minute as it moves past a point.

The 3D Venting Duct system effectively removes resin odor. But we needed to ensure that our solution removes all the harmful VOCs.

Using an air quality monitor, testing was performed with and without ventilation, in a 20'x25' room with closed windows and doors.

The results of using our 3D Venting Duct system are shown in the graph below.

Without ventilation

Using our 3D Venting Duct to vent fumes outdoors

For reference, compare these results with the guidelines from the World Health Organization.

Ensuring a safe resin 3D printing environment requires prioritizing ventilation and incorporating additional methods for your workspace. No single solution used alone will entirely remove the fumes.

3D Printer Ventilation Duct System 8ft with 2x Powered Internal Fans

Share