Beyond the Print: Air Quality Hazards and Ventilation for FDM 3D Printing

1. Introduction: The Rise of Desktop Manufacturing and Its Invisible Cost

Fused Filament Fabrication (FFF) 3D printing, also commonly known by the trademarked term Fused Deposition Modeling (FDM), has undergone a dramatic transformation, migrating from specialized industrial facilities to ubiquitous placement in homes, schools, libraries, and small businesses. This expansion of desktop manufacturing has democratized innovation, but it has also introduced potential health risks that are often overlooked in non-industrial settings. The strategic importance of understanding these associated air quality hazards cannot be overstated. While convenient and powerful, these machines are not benign appliances; they are miniature thermal processing plants operating on our desks. This guide will analyze the primary emissions generated during the FDM process—ultrafine particles (UFPs) and volatile organic compounds (VOCs)—and provide a clear, evidence-based framework for implementing essential ventilation solutions. By understanding the nature of these invisible byproducts, users can create a safer and healthier printing environment.

2. The Invisible Emissions: Analyzing What Your FDM Printer Releases

The FDM process functions by melting a solid plastic filament, a process known as thermal decomposition or degradation. When the polymer chains in the plastic are subjected to high temperatures in the printer's nozzle, some of these chains break. This fracturing releases smaller, lighter molecules that become airborne as Volatile Organic Compounds (VOCs). Simultaneously, some material vaporizes and then condenses into microscopic, solid airborne particles, known as Ultrafine Particles (UFPs). This is not a failure of the process, but an intrinsic result of heating plastic to its melting point.

While FDM 3D printers do not produce visible smoke or exhaust, the process of heating and extruding thermoplastic filaments generates two primary categories of airborne contaminants through thermal decomposition. These emissions are invisible to the naked eye but represent a significant consideration for indoor air quality and personal health. A clear understanding of these distinct emission types is the foundational step toward selecting and implementing effective mitigation strategies.

2.1. The Particulate Threat: Ultrafine Particles (UFPs)

When thermoplastic filaments are heated and extruded through the printer's nozzle, they release exceptionally small airborne particulates known as Ultrafine Particles (UFPs). These particles are defined as having a diameter of less than 100 nanometers. Due to their incredibly small size, UFPs exhibit unique physical behaviors; they act more like a gas than a solid particle, remaining suspended in the air for long periods and moving with air currents. This property allows them to bypass the natural filtration mechanisms of the upper respiratory system and penetrate deep into the human lungs, where they can be absorbed into the bloodstream. The severity of this threat should not be underestimated; studies have found that the concentration of air pollutants near an operating 3D printer can exceed those measured adjacent to a busy highway.

2.2. The Chemical Threat: Volatile Organic Compounds (VOCs)

Alongside UFPs, the thermal degradation of plastic filaments releases a complex mixture of gaseous chemicals known as Volatile Organic Compounds (VOCs). These compounds are the source of the characteristic "plasticky" smells associated with certain materials but are also present even when no odor is detected.

- Source: VOCs are chemical byproducts released as the filament material breaks down under heat. Research has identified a vast chemical signature from this process, with studies documenting more than 200 different VOCs in 3D printer emissions.

- Filament-Specific Emissions: The type and concentration of VOCs emitted are highly dependent on the filament being used. Acrylonitrile Butadiene Styrene (ABS), for example, is well-known for releasing styrene, a VOC that produces a distinct sweet, plasticky smell.

- The Olfactory Fallacy: It is a critical safety principle that the absence of an odor does not signify the absence of emissions. For instance, some materials like ASA may smell less than ABS but can emit even more harmful particles and VOCs. Similarly, PETG produces no discernible smell but still releases airborne particles. Conversely, if a smell is present, it is a definitive indicator that chemical compounds are airborne and being inhaled.

Having identified what is being emitted, it is crucial to understand why these invisible particles and chemicals are a significant concern for human health.

3. The Health Implications: Connecting Emissions to Biological Impact

The invisible particles and chemicals generated by FDM printing are not benign; they have documented and emerging health consequences that range from acute irritation to significant long-term systemic risks. These airborne contaminants can enter the body through inhalation, where they can impact respiratory, cardiovascular, and other systems. Understanding these risks is strategically important, as it provides the necessary justification for implementing the engineering and administrative controls required for a safe printing environment.

3.1. Documented Respiratory and Systemic Effects

Exposure to the combination of UFPs and VOCs from 3D printing has been scientifically associated with a range of adverse health effects. The most commonly reported issues are respiratory in nature, including symptoms consistent with asthma, coughing, and irritation of the eyes, nose, and throat. Systemic effects have also been documented; in one survey of 3D printer users, 15% reported experiencing headaches while operating a printer. These immediate symptoms serve as clear biological indicators that the ambient air quality has been compromised.

3.2. The Critical Link: Airborne Nanoplastics and Cardiovascular Risk

The ultrafine particles emitted from FDM printers are a form of airborne microplastics and nanoplastics (MNPs). While the long-term effects of inhaling these particles are still an area of active research, a recent groundbreaking observational study published in the New England Journal of Medicine provides a critical piece of evidence regarding their systemic impact. The study analyzed plaque removed from the carotid arteries of patients and found a direct correlation between the presence of MNPs and severe cardiovascular events.

Patients with carotid artery plaque in which microplastics and nanoplastics were detected had a 4.53 times higher risk of a composite of myocardial infarction, stroke, or death from any cause at 34 months of follow-up than those in whom they were not detected.

The implication of this finding is profound: it offers the first direct evidence in humans linking the presence of these very types of particles within body tissues to a significantly elevated risk of heart attack, stroke, and death. This establishes a clear and urgent imperative to minimize inhalation exposure, shifting the conversation from a theoretical risk to a documented hazard. The severity of this problem demands a systematic approach to its solution.

4. The Solution Framework: Implementing a Hierarchy of Controls

The hierarchy of controls is a fundamental concept in occupational health and safety that provides a systematic framework for mitigating hazards. This professional methodology can be effectively adapted for non-industrial 3D printing environments to systematically reduce exposure to harmful emissions. The framework prioritizes controlling hazards at their source. For 3D printing, this begins with Substitution (choosing safer materials) and then moves to Engineering Controls (physically removing emissions from the air). This guide will focus on these two most effective tiers to create a safer FDM printing workspace.

4.1. First Line of Defense: Substitution with Lower-Emission Materials

The most effective initial step in the hierarchy of controls is substitution: replacing a hazardous material with a less hazardous one. Whenever a project's technical requirements allow, users should choose filaments with lower documented emissions. Materials such as Polylactic Acid (PLA) and Polyethylene Terephthalate Glycol (PETG) generally produce significantly fewer UFPs and VOCs, largely due to their lower required printing temperatures and more stable chemical composition, than higher-emission materials like Acrylonitrile Butadiene Styrene (ABS) or ASA. Making a conscious choice at the material selection stage can dramatically reduce the contaminant load from the very start.

4.2. Essential Engineering Controls: Effective Ventilation Strategies

For any FDM printing operation, active ventilation is the most critical engineering control for ensuring a safe breathing environment. This involves physically removing contaminated air from the operator's workspace.

- Baseline Ventilation: The absolute minimum measure for operating an FDM printer is to do so in a large, open, and well-ventilated room, preferably with an open window to allow for air exchange. However, this method relies on passive air movement and should be considered a temporary, minimal precaution, not a comprehensive long-term solution.

-

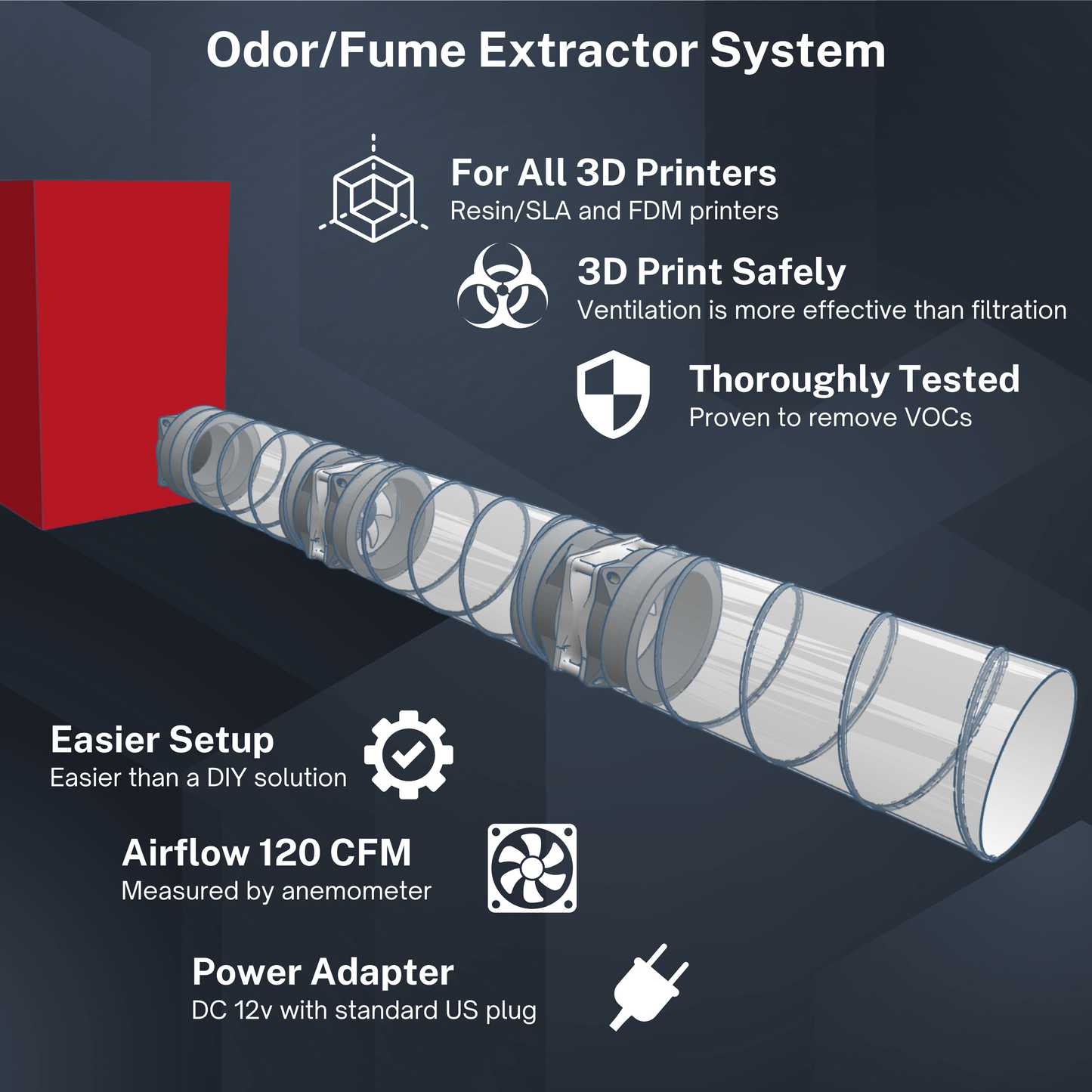

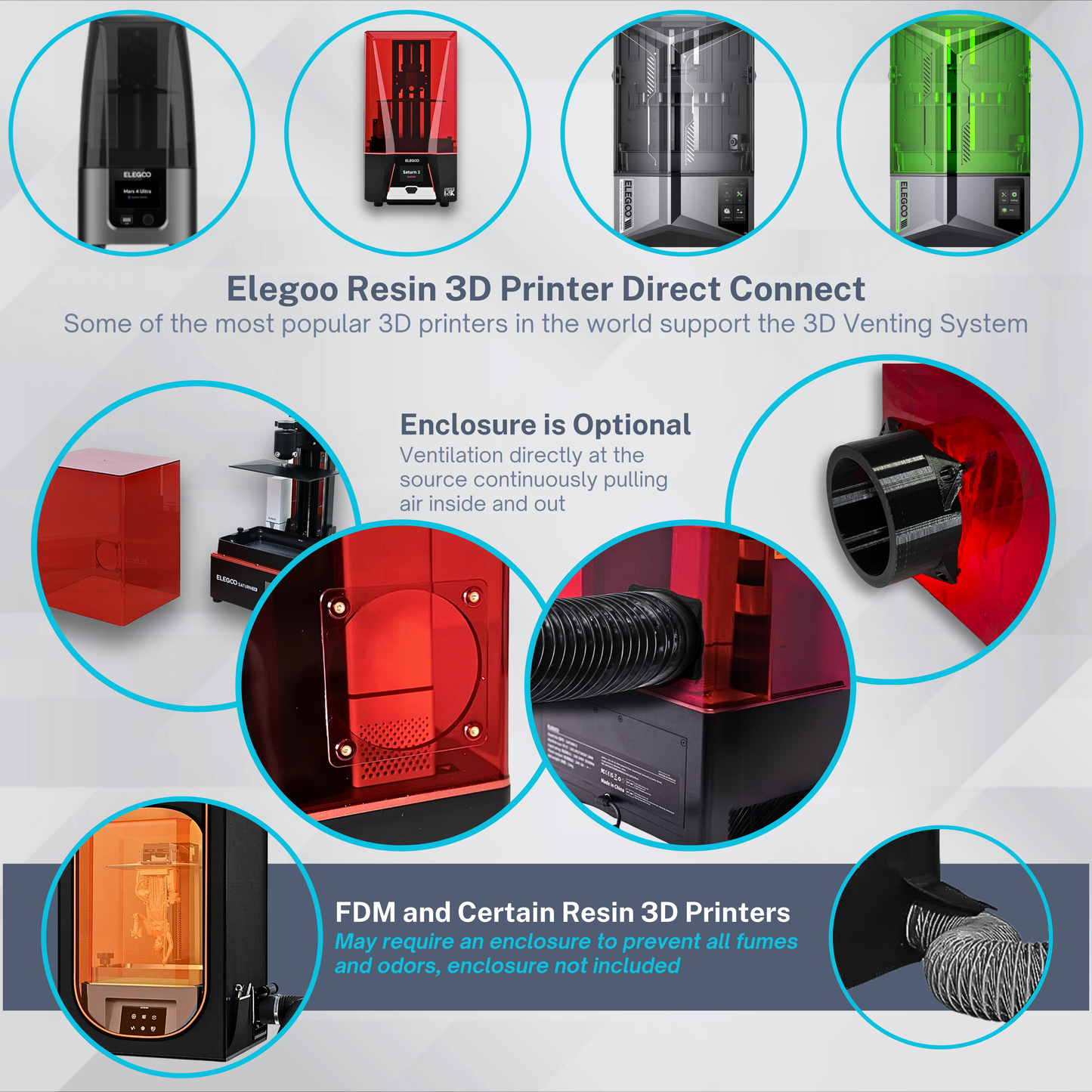

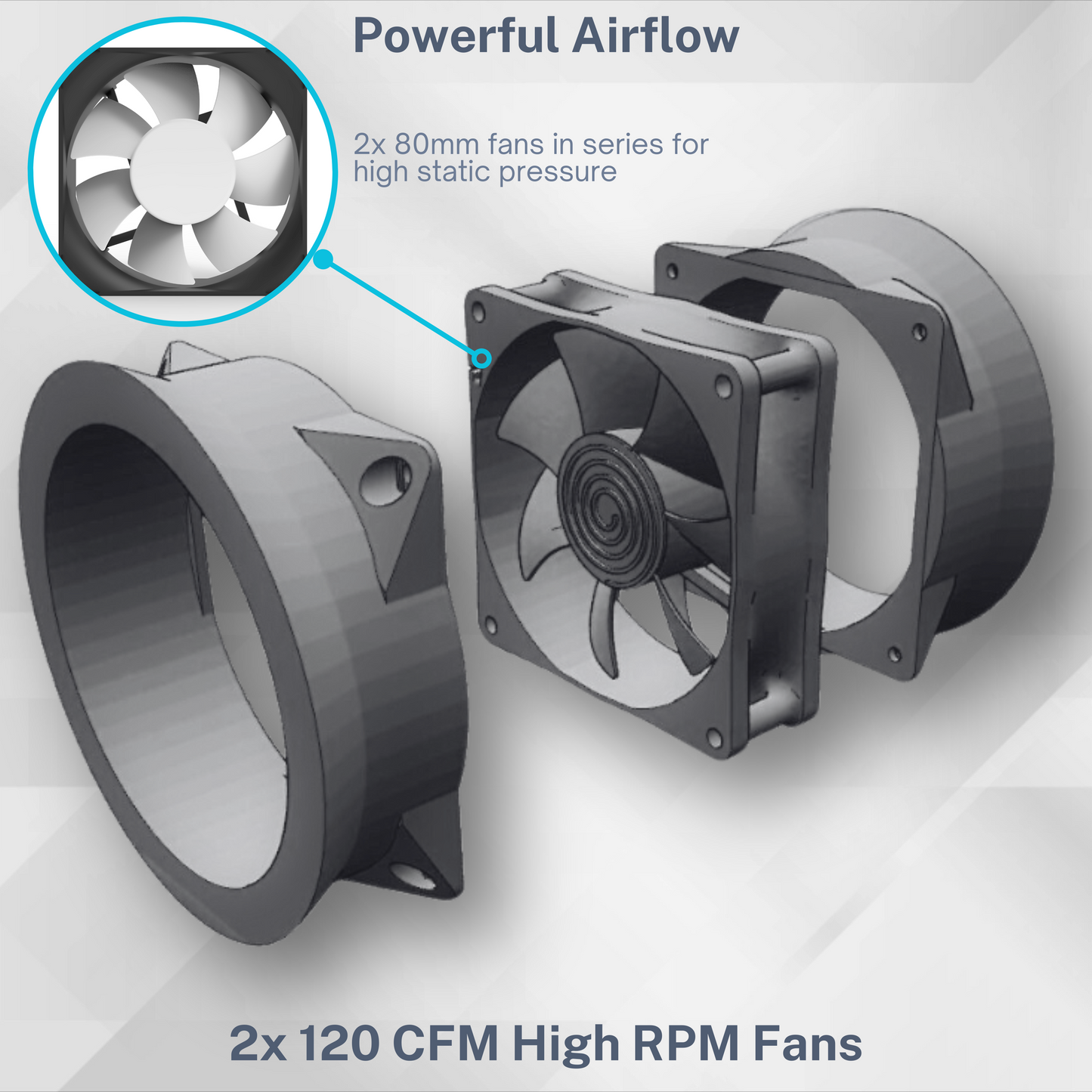

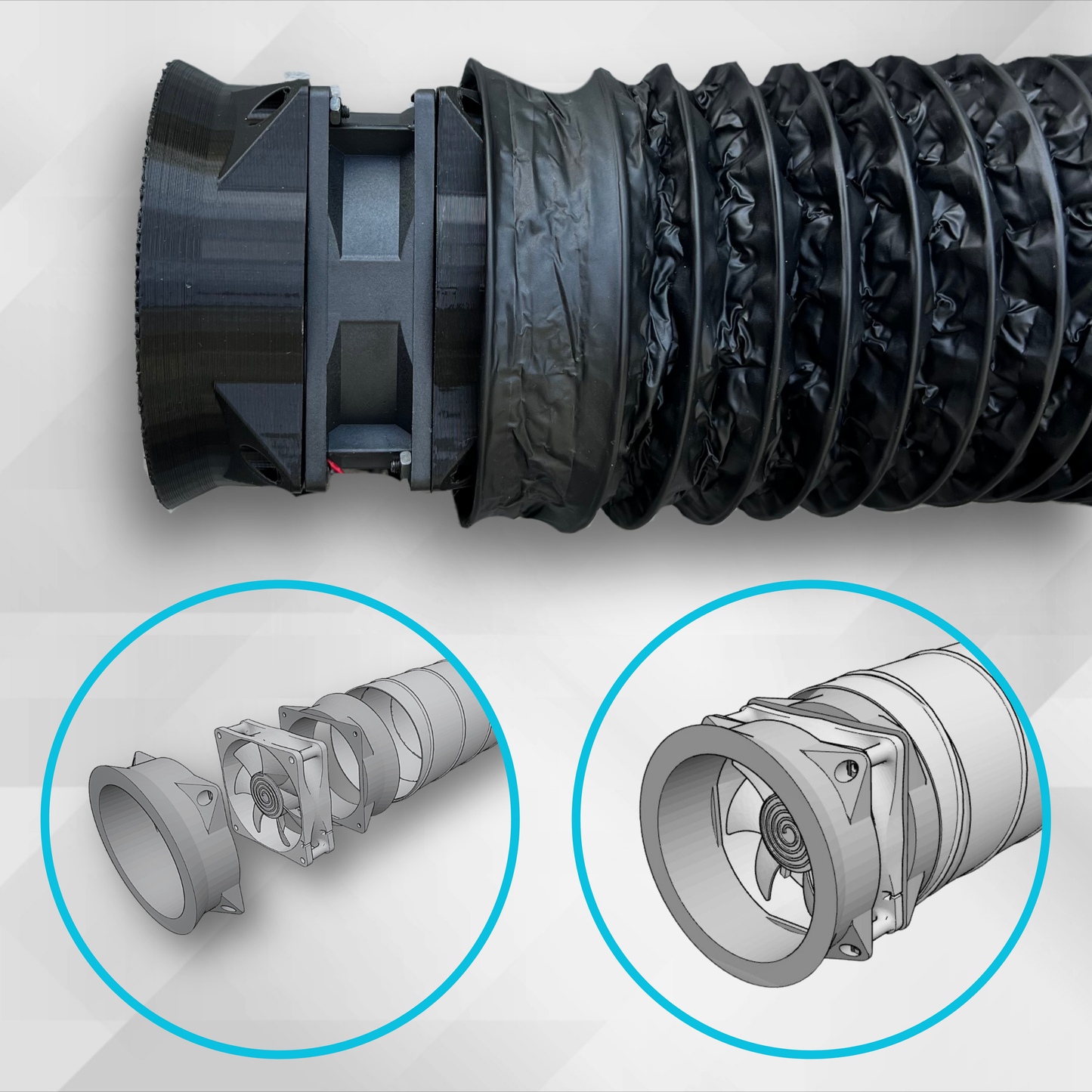

Ideal Solution: Local Exhaust Ventilation (LEV): The preferred and most effective engineering control is a Local Exhaust Ventilation (LEV) system. An LEV system is designed to capture contaminated air directly at its source—the 3D printer—and exhaust it safely outdoors before it can mix with the air in the room. A practical and highly effective LEV setup for a home or small business can be assembled from readily available components:

- Containment: Place the 3D printer inside a dedicated enclosure. Commercially available fabric "grow tents" are an excellent, cost-effective option for this purpose.

- Extraction: Connect the enclosure to an inline exhaust fan using flexible ducting. The fan provides the motive force to pull air out of the enclosure.

- Exhaust: Route the ducting from the fan's outlet to a window adapter, which allows the captured emissions to be vented directly outside.

- The Negative Pressure Principle: This LEV configuration works by creating a state of negative pressure inside the enclosure. The inline fan constantly pulls air out, ensuring that air from the room flows into the enclosure through any small gaps or openings. This inward airflow prevents contaminated air, UFPs, and VOCs from leaking out into the breathing zone.

- A Critical Warning on Enclosures: An enclosure by itself provides no significant air quality benefit. In fact, by trapping emissions, a sealed, unventilated enclosure may expose the operator to a concentrated plume of contaminants when the door is opened. To be effective as a safety device, an enclosure must be actively ventilated as part of a complete extraction system.

4.3. Supplemental Strategies: The Role of Air Filtration

Air filtration should be positioned as a secondary defense, best used in conjunction with ventilation or in situations where direct outdoor exhaust is not feasible. It is important to select the correct filter type for the target contaminant.

|

Filter Type |

Target Contaminant |

Key Considerations |

|

HEPA Filter |

Ultrafine Particles (UFPs) |

High-efficiency filters (e.g., HEPA, EPA12) are rated to capture 99.5% or more of airborne particulates. |

|

Activated Carbon |

Volatile Organic Compounds (VOCs) |

Absorbs VOCs like a sponge, but has a limited lifespan and becomes saturated over time. Less effective in small, low-contact-time filters. |

For users in dense urban areas where outdoor air quality may also be poor due to traffic or industrial pollution, a "Vent, Then Purify" strategy is recommended. This involves two distinct steps:

- During printing, use the LEV exhaust fan to remove the high concentration of printer-generated VOCs and particles from the immediate printing space.

- After the print is complete and the LEV system is turned off, close the windows and use a high-quality standalone room air purifier (with both HEPA and carbon filters) to scrub the remaining fine particulates (PM2.5) and other pollutants from the indoor air.

5. Conclusion: Adopting a Proactive Stance on Printing Safety

While Fused Deposition Modeling is a revolutionary technology that empowers creators and innovators, it is essential to recognize that the process generates hazardous ultrafine particles and volatile organic compounds. As the scientific evidence clearly indicates, these emissions are linked to tangible health risks, from respiratory irritation to a significantly increased danger of severe cardiovascular events. The most critical takeaway from this guide is that safety cannot be an afterthought. Implementing a proper ventilation strategy, particularly a Local Exhaust Ventilation (LEV) system that captures emissions at the source and exhausts them outdoors, is the single most important step any user can take to protect their health. We urge all members of the 3D printing community to treat air quality not as an inconvenience, but as an integral and non-negotiable part of the printing process itself. A proactive approach to safety ensures that the benefits of this remarkable technology can be enjoyed for years to come without compromising personal well-being.